|

Journal Club meets Thursdays in the Physics Library >> Weekly Articles |

Surface, Interface and Nanostructure Research Group |

||

Research |

Group Focus |

||

| Discuss our main research interests here |

Lab Capabilities |

||

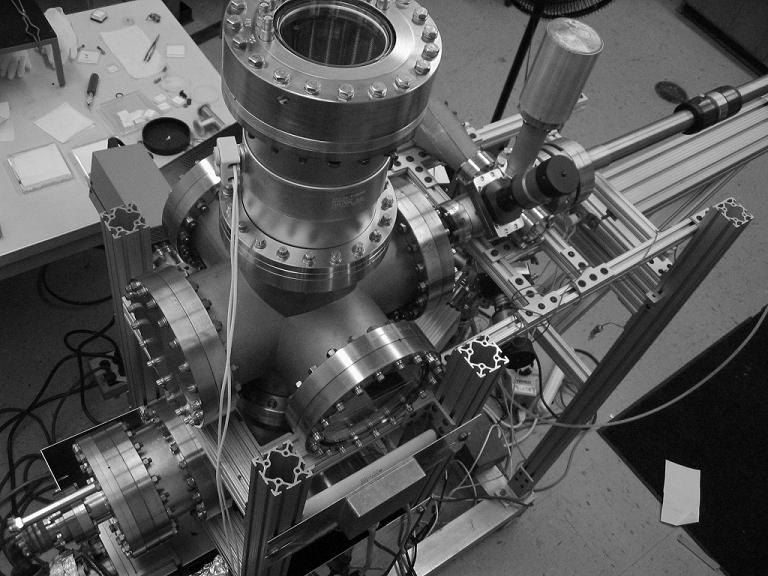

First Floor LEED/Auger System |

||

The first floor LEED (low energy electron diffraction) system was specifically designed for the purpose of taking samples from air pressure down to a UHV environment in as little time as possible. To accomplish this, two load lock chambers are built onto the system. During a typical sample transfer, the first chamber is vented to air pressure. The sample is then placed in the chamber and pumped on with a turbo molecular pump. After a few minutes, the chamber can then be opened to a second chamber. The second chamber acts as a buffer between the first chamber and the main chamber where the LEED is located. By utilizing a second load lock, the pressure gradient between load locks is minimized and the amount of contaminants such as water vapor particles is greatly reduced. The result is a much shorter pumping time before data can be taken. Once the second chamber is opened it is taken into the main chamber via transfer arm, where it can be studied using LEED and Auger techniques. |

||

|

||

|

|

||

This system's main purpose is for scanning tunneling microscopy and spectroscopy under ultra high vacuum at room temperature. It is equipped with a custom in-house built STM featuring:

|

||

|

| ||

The low temperature system has the ability to efficiently swap samples and tips without breaking Ultra High Vacuum. A furnace has also been included in the chamber allowing us to create graphene from SiC samples, which are then placed in the stm and are cooled to temperatures ranging from room or liquid helium temperatures. We are then able to use the systems capabilities to perform test ranging from LEED, STM, capacitance, dI/DV and BEEM to further understand graphene's physical characteristics. For a more in-depth view of they systems design please refer to An ultrahigh vacuum cryogenic scanning tunneling microscope with tip and sample exchange. Currently Kevin and Lee are busy upgrading the systems transfer system and operating structure, though throughout this process the Low temperature system is often being used to better the process of bettering epitaxial methods and is gleams as much information as possible with each passing sweep of its piezos.

|

||

| © Copyright 2006. | Design by Interspire |